Introduction

The slotter machine falls under the grouping of the reacting kind of machine instrument like a shaper to a shaper or a coordinator. It works practically on a similar standard as that of a shaper.

The critical qualification between a slotter machine and a shaper machine is that in a slotter the crush holding the gadget reacts in the vertical rotate. though in a shaper the smash holding the instrument responds in a level pivot. A vertical shaper and slotter machines are basically similar to one another as regards their turn of events, movement, and use.

The solitary contrast being, on account of a vertical shaper, the slam holding the device may likewise respond at a point to the even table notwithstanding the vertical stroke. The slam can be turned not more than 5° to the vertical.

The slotter machine is utilized for –

- Cutting scores, keyways and spaces of different shapes.

- Utilized for making standard and unpredictable surfaces both inside and outer.

- For dealing with enormous and off-kilter workpiece.

- For cutting inward or outside cog wheels and numerous different activities which can’t be effortlessly machined in some other machine instrument portrayed previously.

Types of Slotter Machine

- Puncher slotter.

- Precision slotter.

Puncher Slotter

The puncher slotter machine is a weighty, inflexible machine intended for evacuation of a lot of metal from huge forgings or castings. The length of stroke of a puncher slotter is adequately enormous. It could be up to 1800 to 2000mm.

The puncher slotter smash is typically determined by a twisting pinion fitting with the rack teeth cut on the underside of the slam. The pinion is driven by a variable speed reversible electric engine like that of a planer. The feed is additionally constrained by electrical pinion wheels.

Precision Slotter

The accuracy slotter machine is a lighter machine and is worked at high rates. The machine is intended to take light cuts giving the precise completion.

Utilizing unique dances, the machine can deal with various chips away at a creation premise. The exactness slotter machines are likewise utilized for broadly useful work and are typically fitted with Whitworth brisk bring instrument back.

Slotter Size

The size of a slotter machine like that of a shaper is determined by the greatest length of stroke of the slam, communicated in mm. The size of a broadly useful or accuracy slotter normally goes from 80 to 900mm.

To indicate a slotter effectively the breadth of the table in mm. Measure of cross and longitudinal travel of the table communicated in mm. The quantity of velocities and feeds accessible, h.p. of the engine, floor space required and so forth ought to likewise be expressed.

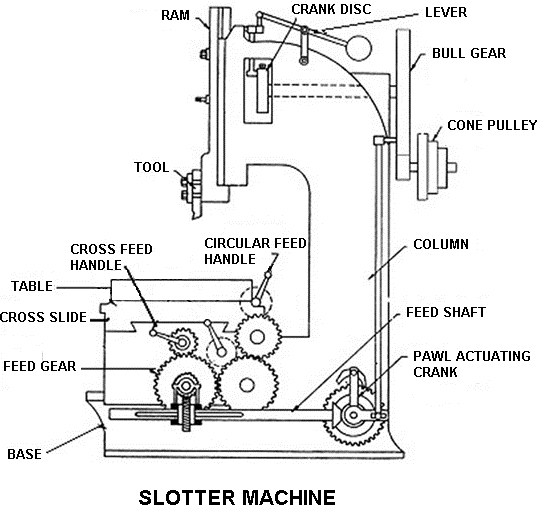

Parts of Slotter Machine

Base or Bed

- The base is unbendingly worked to take up all the cutting powers and the whole heap of the machine.

- The highest point of the bed is precisely completed to give guideways on which the seat is mounted.

- The guideways are opposite to the segment face

Column

- The segment is the vertical part which is projected indispensably with the base and houses driving component of the slam and taking care of system.

- The front vertical face of the segment is precisely completed for giving manners by which the smash responds.

Saddle

- The seat is mounted upon the guideways and might be pushed toward or away from the segment either force or manual control to supply longitudinal feed to the work.

- The top substance of the seat is precisely completed to give guideways to the cross-slide. These guideways are opposite to the guideways on the base.

Cross-slide

- The cross-slide is mounted upon the guideways of the saddle and maybe moved parallel to the face of the column.

- The movement of the slide may be controlled either by hand or power to supply crossfeed.

Rotary Table

- The rotational table is a round table which is mounted on the highest point of the cross-slide.

- The table might be pivoted by turning a worm which networks with a worm gear associated with the underside of the table.

- The turn of the table might be affected either by hand or force.

- In certain machines, the table is graduated in certificates that empower the table to be turned for ordering or plunging the outskirts of an employment in the equivalent number of parts.

- T-openings are cut on the top substance of the table for holding the work by various clasping gadgets. The turning table empowers a roundabout or shaped surface to be produced on the workpiece.

Ram and Toolhead Assembly

- The ram is the reciprocating member of the machine mounted on the guideways of the column. It supports the tool at its bottom end on a tool head.

- A slot is cut on the body of the ram for changing the position of the stroke.

- In some machines, special type for tool holders is provided to relieve the tool during its return stroke.

Ram Drive Mechanism

A slotter eliminates metal during descending cutting stroke just though during upward return stroke no metal is taken out. The diminish the inactive return time snappy return instrument is fused in the machine. The standard sorts of slam drive component are,

- Variable speed reversible motor drive mechanism.

- Hydraulic drive mechanism.

- Whitworth quick return mechanism.

Ess kay is the one of the best slotter machine manufacturer and supplier in India. We are known for our quality, we provide to our clients. We have a large number of client base at both National level and International level. Contact us to get the best quotations. We also supply various other types of machines as well like lathe machine, shaper machines, CNC, Power Press Machines, hydraulic brake, slotting machine, surface grinder, Milling Machine etc.