We Esskay Lathe and Machine equipment in Batala offer a Wide Range of Slotting Machines that gave Stroke alteration Facility changes from various sizes that are the up-to-the size of machine-like on the off chance that machine limit is 300 mm, at that point a modification should be possible from 10 mm to 300 mm.

We are making slotting machines from 200 mm to 900 mm. we are a Manufacturing CNC slotting machine with table size 1500 mm and stroke limit 600 mm, the heaviness of the machine is 10 tons, India’s Biggest slotting machine ever.

We Esskay Lathe and Machine Tools give constant stroke in all sizes of slotting machines and each stroke taking a shot at fundamental gear teeth. With the assistance of constant stroke, gears have excessively unbending and solid, we have done nitrite treatment on Gears, and it assists with attaining the precision of the component.

The cost of slotting machines fluctuates from size to estimate, we are slotting or opening machine producers in Batala, we are the greatest slotting machine maker in Punjab,

we are utilizing Helical gear in our slotting machine. It is produced using GCI-25 Grade projecting. With the assistance of helical gears, we accomplish more exact work. It prevents breaking of riggings over and over,

Advantages of Helical Gears:

For quiet and smooth activity.

The usage of helical gears

Decrease the noise level.

Twofold Load taking limit and long life.

Appropriate in harsh work. No compelling reason to change in 10 years.

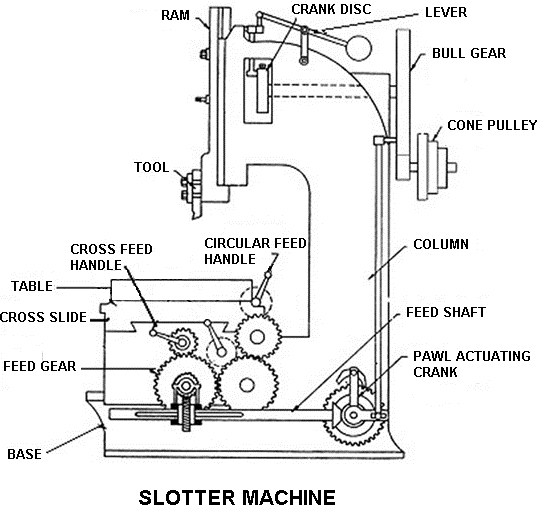

Y-Axis – the fundamental slide is a significant piece of the slotting machine. Accuracy and productivity rely upon Y-Axis. So our master engineers put their best attempts while building this machine.

Highlights of our Stroke Ram/Spindle:

Our stroke ram is 900 mm long.

It is produced using CI material with appropriate grinding and wrapping up.

The straightness and parallelism of our stroke ram are 10 microns.

For good accuracy, we are checking and testing each piece with a straight edge. One significant element of our Spindle is tradable. Now and then as a result of harm and different issues, the client necessitates those parts. So around then, they can exchange that part effectively and rapidly.

The base of the Slotting machine legitimately impacts the inflexible nature and vibration of the machine.

The most extreme cutting limit in MS Material is 12 mm by Foam instrument.

We are trying and working the machine in the wake of checking the base level as a right.

We are utilizing Gun Metal Bush to interface the road. It is a chrome-plated nut, so it is dustproof.

The advantage of Using Gun Metal Bush :

Some of the time when oil gets over in a pump or administrator neglects to grease up oil, there is no possibility of any harm in the base in light of that nylon nut. Indeed, even it additionally increments the life of Connecting road.

We generally feel that the machine ought to reach securely on the client’s floor. So considering transport issues and clients’ accommodation, we are giving throwing hook inbuilt with the machine. The reason to give such a choice is to transit machine securely and with no harm. Our throwing hook conveys weight up to 10000 kg without any problem.

Different shaft size differs with various materials. It differs from the material, weight, and size of the activity. So considering this we have given a choice of the 3-speed pulley in our machine so the client can work it at three different steps. Speed can differ for productive filling in according to the weight and size of the activity, material sort of the activity.