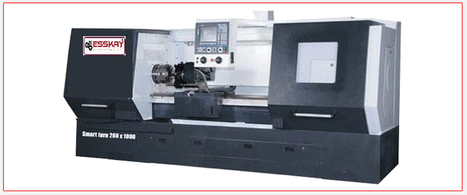

What is Lathe Machine?

A lathe machine can be explained as the shaping tool that turns a part on a rotating shaft to accomplish various operations such as deformation Drilling, knurling, sandling, cutting etc.

With the help of this machine tool that are made out of the workpiece to create objects with center axis.

Esskay Lathe machines and tools will tell you about the lathe machine and the various operations which could be done with the help of this machine.

The various operations that can be done with the help of lathe machine are as follows:-

1. Turning

2. Facing

3. Taper turning

4. Knurling

5. Grooving

6. Parting off

7. Electric turning

8. Thread cutting

9. Reaming etc.

Operation of Lathe Machines

The lathe machines are excellent for application like shaping pottery. An excellent example is a Potter’s Wheel. Most acceptable provisioned for metal working lathes. These can also be taken into consideration for production of solids of rotation, screw threads, helices and plane surfaces. Fancy lathes are able to fabricate three dimensional solids with staggering complication. The workpiece is normally clasped by one or two holders. Where an individual is able to move that part horizontally to adjust working on the piece lengths. The few other holding techniques include clamping at the rotation of axis with help of collet or chuck, face plate, clamps etc.

1. Turning:-

Turning is the most usual sort of operation carried in almost every single lathe machine ever produced. Turning can be explained as the process of getting rid of the extra material form the workpiece to generate a cylindrical surface to the required length. The workpiece is placed right between the centre and spinned at the desired pace. The lathe machine then starts making a movement in the longitudinal direction in order to move towards the headstock along the perfect cut of depth. The surface finish is absolutely good.

2. Facing:-

It is a process of diminishing the total length of the piece by putting it into the square which leads to the axis of lathe. The process of decreasing a surface that is flat at the endpoint of the workpiece. The chopping edge of the sharp toll could be considered as the height same as of the workpiece centre.

3. The Chamfering Process:-

The Chamfering process can be defined or explained as the obtaining of the bevelled surface at edge of a workpiece that is cylindrical in geometry. The process is accomplished just when the shaft and bolt ends. The Chamfering plays an excellent role to avert from the damages to the very sharp edges and safeguard the process for the people operating the lathe while engaged in other work. Chamfering on bolt plays a crucial role to hold the screw (nut) fimly.

4. Knurling operation:-

The knurling operation is the process of attaining a diamond structure on the workpiece in order for a little assistance for grip it more perfectly. A proper or perfect grip is the main reason when the surface is administered by hands only. This twisted task can only be done with the knurling tool. This smart mechanism comprises of a station of accustomed steel roller and is able to hold the toolpost much rigidly. The fact is knurling is supposed to be done at an extremely low speed. It is applicable/useful on the handles and ends of gauges. The feed varies completely between 1 to 2 mm per coupe. At Least three to two cut is essential to furnish with full potential.

5. Thread cutting:-

It is the significant process in which the lathe needs to acquire the steady spiral cut better known as threads. Whenever such threads or spiral cuts are created on the outer surface on the workpiece is known as outward thread cutting. The threads or spiral cuts are created in the inner surface on workpiece is known as internal thread cutting. This workpiece is revolving in and around 2 centres i.e. dead and live centres or the lathe. The smart mechanism is then advanced vertically to acquire the needed type of the thread. The tool when preceded from the right direction to the left direction one can get the left handed thread. Likewise whenever the progressed from left to right one can have the right handed thread. The movement of the carriage here is furnished with the lead screw. A couple of change in the gears moved the lead screw by moving around the handle which is the depth of cut can be administered.

6. Filling:-

This is said to be concluding procedure which comes into the picture right after turning. It is carried on lathe to get rid of burrs, sharp corners and the trail marks on workpiece while also in an attempt to drag it to the size by eliminating even the smallest metal traces. The entire process comprises of getting a flat single cut file through and over the workpiece that revolves at a high pace. The pace is normally 2 times as compared with turning.

7. Polishing:-

This work comes into action when the filing is done in order to get the surface quality improvised workpiece. If the polishing is done with the finest quality emery cloth right after filing is done successfully delivers in extremely smooth and bright surface. The lathe runs at a rate of 1500 to 1800 rpms and oil is taken into consideration on the emery cloth.

8. Grooving:-

It is the task of eliminating the workpiece diameter when it has a really tapering surface. And it could be done only with the help of the grooving tool. A grooving tool is identical to the detachment tool. It is quite normally done at the edge of a thread which falls adjacent to the shoulder in order to leave a tiny border.

9. Spinning:-

It is the task of the creating a minute metal sheet by turning the lathe machine at a higher pace and then pushing it against a headstock axle. Reinforcement is needed from the tailstock edge.

10. Forming:-

It can be explained as the task of transforming a convex, concave or of any asymmetrical structure.

11. Drilling:-

Drilling is the process of creating a hole that is of a cylindrical shape in the wall. It can be done with the help of a rotating rotating mechanism. The rotating part of the slicer better known as the drilling drill. During this procedure the workpiece us moving in and around a faceplate, or a chuck and the drill is held against the drill holder of the tailstock and the chuck of the drill chuck. The material is pulled out and is impacted by the motion on the tailstock axle. This technique is accepted widely for the drilling shaped workpiece.

12. Reaming:-

Reaming is the process which could be explained as the task of finalizing and classifying a hole which already has been bored or drilled. The mechanism is known as reamer which comes fitted with multiple plate cutting fringes. The reamer is held up against a tailstock axle, directly or through the drill chuck and is uphold at a fixed destination while the work is revolved at a very slow pace.

13. Boring:-

Boring is the task of expanding of the hole which has been drilled already, forged, puched. However it cannot result into a hole. Boring is identical to the exterior turning task which can be carried out in a lathe. In this procedure the workpiece is rotated in a faceplate or chuck and the mechanism are fixed into the work. It comprises of a boring bar that just has one single point cutting mechanism which expands the hole. It also rectifies the cylindrical-ness of a hole. This technique is adopted for boring tiny sized jobs only. The only thing is that the pace of the process is slow.

14. Tapping:-

Tapping is explained as the procedure of slicing the threads of small diameter threads that are at the interior while taking into consideration a multi-cutting mechanisms better known as the tap. A lather the object is upheld on a faceplate or on a chuck and whirled at a very slow pace. A tap of the needed expanse is upheld against the axle.

Conclusion

Above mentioned are some of the terms needed to be acknowledged before understanding what is a lathe machine operations and how it works. So far Esskay lathe machines and tools the well named Lathe machine manufacturer have covered all the important operations that are accomplished with the lathe machine.