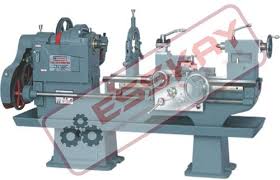

Lathe Machine

The lathe machine is a kind of machine where in work item is rotated on the axis to do the operations like cutting, turning, drilling, boring etc.

Lathe Machine Cutting Tools

Maximum times, single point cutting tools are used for general work, and multi point cutting tool is used for special operation only. Lathe machine cutting tools are further categorized as per the method of using tool and feed mechanism

A) As per the method of using tool

1. Turning Tool

Under the category of turning tool, cutting tools are further classified as

- Rough Turning Tool – The main function of the rough turning tool is to shed the maximum chunk of unwanted material of work piece with in the minimum time span.

2 Finish Turning Tool- the main function of the finishing tool is to add finishing touch to the work piece once the major chunk is removed by the rough turning tool. This tool works with precision.

2. Chamfering Tool

Chamfering tool is used to finish the edges of the work item to prevent the breakage from the uneven edges.

3. Shoulder Turning Tool

When your work item has different diameters and cutting tools used to machine the all diameter by moving from one to another diameter it is called shoulder and hence the tool is called should turning tool.

4 . Thread Cutting Tool

Thread cutting is one of the most important operations of the lathe machine. Thread cutting tools are further classified as external and internal thread cutting tools. Principle of both thread cutting tools is the same and there is different of tool and location of the work item.

5. Facing Tool

Facing tool of lathe machine is used to flat the surface of the work item and also used to limit the work in the required length. In the facing operation, the tool is adjusted in a perpendicular position to the axis of the work item. It is also a kind of finishing tool.

The length of the facing tool ranges from 125 mm, 140, 170, 200 to 240 mm.

6. Grooving Tool

Grooving is done on the work item to make it fit for the grinding operation without touching shoulders and it makes the nuts to move smoothly.

7. Forming Tool

Forming tools are further classified as simple forming tools and flat dovetail forming tool. The purpose of forming tool is to impart the predefined shape to the work item.

8. Boring Tool

The basic purpose of the boring tool is to bore the hole in work item in the required depth and diameter. The boring tool is affixed the boring bar and boring operation is performed.

9. Counter boring Tool

Counter boring tool in the lathe machinery performs the operation of expanding the original hole bored. It is basically done to provide space to bolts, studs etc. The counter boring operation can be performed by an ordinary boring tool.

10. Under cutting Tool

Under cutting tool is similar to the grooving tool. In this also clearance angle is provided on all sides of the tool.

B). As per feed Mechanism

1. Right-Hand Tool

A right-hand tool is used to feed on tailstock to the headstock while performing operations like turning, cutting, etc. A right-hand tool is located on its left-hand end.

2. Left-Hand Tool

A left-hand tool is used to feed on the head stock to the tail stock ie left side of lathe bed to the right side.

3. Round Nose Tool

This is turning toll and can be fed either from the left side of lathe bed or from the right side to the left side of the lathe bed.Esskay machine tool is one of the renowned Lathe machine manufacturer who also deals in drilling machine, power press machine, hydraullic machine manufacturing.